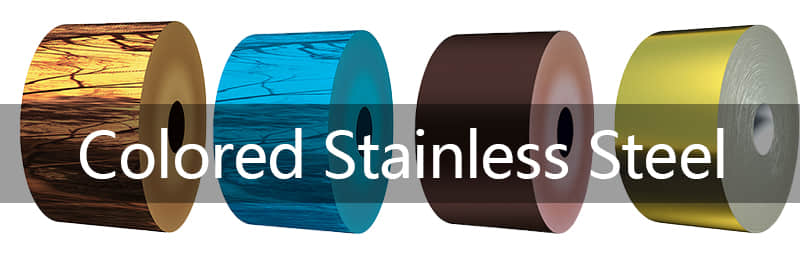

Colored Stainless Steel

What is colored stainless steel

Colored stainless steel is the normal stainless steel that was colored through Physical Vapor Deposition(PVD) coating. The color process is like to form a thin chrome oxide layer on the surface of stainless steel, with controlling the thickness of the oxide layer, we can get various colors, from gold to blue, bronze, purple and green.

Layer thickness ranges from 0.02 µm to 0.37 µm, and it relates to the darkness of the color, the thicker, the darker. The surface can be any color, but the base is still the same natural stainless steel silver. As the surface is just coated with a chrome layer, so it will scratch, so the finished products are covered with PVC film to protect it from scratching.

Main Grade of colored stainless steel

As it is mainly used in decoration, so in the market, main stainless steel grade is 201 and 304. 316 grade is not wildely applied as it costs more than the 304 and 201 grade.

Applied Standards:JIS, AISI, ASTM, DIN, TUV,BV,SUS,etc.

The Quality of colored stainless steel

The quality of colored stainless steel is the same with normal quality stainless steel. Basically, the price tells the quality, you can choose the material according to your applications.

Normal Sizes and Thickness

| Normal Sizes | Normal Thickness |

|---|---|

| 1000mm*2000mm | 0.3mm |

| 1219mm*2438mm | 0.5mm |

| 1219mm*3048mm | 0.7mm |

| 1219mm*4000mm | 1.5mm |

| 1500mm*3000mm | 2.0mm |

Basic colors

- Gold

- Champagne

- Rose Gold

- Red

- Green

- Purple

- Sapphire Blue

- Black Titanium

Or you can choose according to the color code below

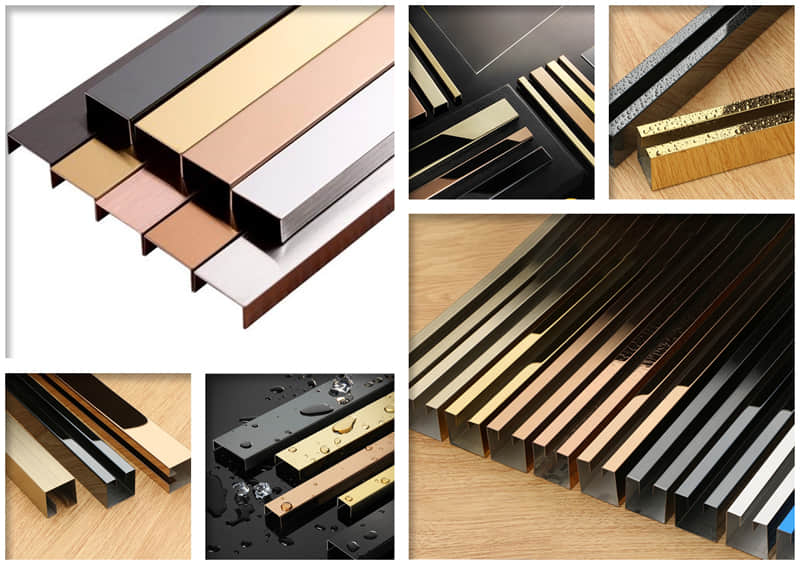

Our services on the color Stainless steell

- Etching

- Copper layer coating

- Anti Finger Printing

- Auto Pick and Place machines

- PVD Coating for Fabrications

- PVD Coating as Horizontal Operating

- Cutting to Length

- Super Mirror Polishing

- Vibration, Bead Blast, Cross Hairline

The processing of PVD Coating

The factory Show

<img data-cke-saved-src="https://imgur.com/elkVWM8.gif" src="https://imgur.com/elkVWM8.gif" alt="the cutting machines>

<img data-cke-saved-src="https://imgur.com/elkVWM8.gif" src="https://imgur.com/elkVWM8.gif" alt="the cutting machines>

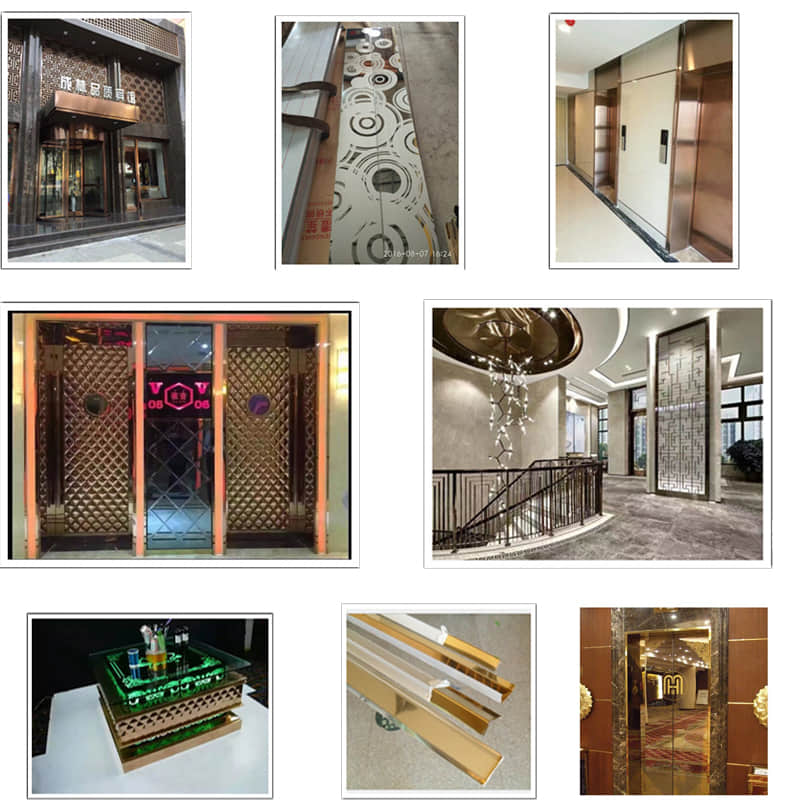

Colored stainless steel applications

The colored stainless steel can be more beautiful, and it can be used in decoration like the kitchen babinet, closet, elevator panels, tableware, screen panels.

Packing and Delivery

- Best surface protection--Sheets are covered with PE film

- Strongest protection--with wooden package in transportation.

- Avoid damages in advance--fixed by strong metal strings, shoring.

- Perfect Service--detail pictures and news will inform clients in time.

- Quickest Transportation will be arranged according to client's needs.

FAQ

Q1.How can I get some samples?

A1.Small samples are in store and can provide the samples for free. A catalog is available, most patterns are ready samples in stock. Customized samples will take about 5-7days.

Q2.What do you do to control your quality?

A2. From technology, our product is by 3 coatings and 3 baking. From the quality inspection, we have QC engineers responsible for Incoming Inspection, Processing Inspection, and Finished Product Inspection.

Q3.If the order is too large, can you ensure in time delivery?

A3.Sure! Our factory with high productive force and we have the advanced technology devices which make us ensure on-time delivery.

Q4.How to protect the stainless steel sheets?

A4.Two white and black PE layers to cover the surface, each layer is 70 micro (Total 140 micro), laser PVC is also workable.( Novacel or poli-film brand )

-lp.jpg)